THE DESIGN AND CONSTRUCTION OF A PHOTOVOLTAIC SYSTEM

TO GIVE 2KW OF POWER WITH THE USE OF A SOLAR PANEL INVERTER

BY

AKHERE

INNOCENT OSE

MATRIC NO:

FNS/PHY/15/21899

FACULTY OF

PHYSICAL SCIENCE,

AMBROSE ALLI

UNIVERSITY,

EKPOMA –

NIGERIA.

DECEMBER,

2019

MATRIC NO:

FNS/PHY/15/21899

A PROJECT

WORK SUBMITTED TO THE DEPARTMENT OF PHYSICS, FACULTY OF PHYSICAL SCIENCE,

AMBROSE, ALLI UNIVERSITY, EKPOMA, EDO STATE, NIGERIA. IN PARTIAL FULFILLMENT OF

THE REQUIRMENTS FOR THE AWARD OF BACHELOR OF SCIENCE DEGREE (B.Sc.) HONS DEGREE

IN PHYSICS.

CERTIFICATION

This is to certify that this project work carried out by Akhere Innocent Ose with matriculation number, FNS/PHY/15/21899 in the Department of Physics, Faculty of Physical Science, Ambrose Alli University, Ekpoma, Edo State, Nigeria.

___________________ _________________

Dr. S. Ehika Date

Supervisor

___________________ _________________

Dr. R. O. Okanigbuan Date

Head of Department (Physics)

__________________ _________________

External Examiner Date

DEDICATION

This project work is dedicated to God Almighty for his unending love, grace, provision, protection, favour, mercies and wisdom upon my life throughout the course of this project. Also, I dedicate this work to my wonderful parents, Mr. & Mrs. Goddy Oahimire Akhere, who never gave up on me with their prayers, I am forever grateful.

ACKNOWLEDGMENT

I wish to express my profound gratitude to God Almighty for his love, grace, wisdom, protection and provision during the course of research and writing this project.

My profound gratitude goes to my supervisor, Dr. S. Ehika with whom my skills and potentials constantly advanced as he taught me to apply my skill to different range of subject areas and helped me organize my time effectively and think about the commercial viability of all that I learnt.

My special thanks go to the head of department (Physics), Dr. R. O. Okanigbuan and other academic staffs; Professor Emeritus J.E.A. Osemeikhian, Dr. G.K. Oyanna, Professor O. Ujuanbi, Professor Isaac Aigbedion, Professor S.E. Iyayi, Dr. S.I Jegede, Mr. S.O Salufu, Dr. O.J. Ataman, Mr. K.O. Ozegin, Dr.O.E. Akhirevbulu, Dr. A. Iyoha, Dr. C.V.O. Amadasun and Mrs. Anita Odeh; my special thanks goes to the Non-Academic Staff. You all contributed to my success, God bless you all.

To my exceptional parents, Mr. & Mrs. Goddy oahimire Akhere, my siblings, and My Uncle, Evang. & Mrs Akhabue Airiede Matthew, whose love and support sailed me through my days of academic exercise in this institution. I am sincerely grateful for your unquenchable love, endurance and support, God will continually bless and keep you.

Finally, to my friends, Mary, Jerry, Liberty, Samuel, Smart, David, John, Diana, Ugochukwu, Blessed, Maxwell, Darlington, Theophilus, Samson. who helped me with their resources to accomplish this task and others I could not mention due to space limitation, who might have contributed directly or indirectly to the successful completion of my program, I appreciate you all.

TABLE OF CONTENT

Title Page

Certification

Dedication

Acknowledgement

Table of Content

Abstract

Chapter One

Introduction

1.1 Solar Energy

1.2 Uses of Solar Energy

1.2.1 Heating

1.2.2 Cooling

1.2.3 Transportation

1.2.4 Generation of Electricity

1.3 Basic Principle of Solar Inverter

1.4 Need of Solar Inverter

1.5 Types of Solar Inverter

1.5.1 Stand Alone Inverters

1.5.2 Grid Tie Inverters

1.5.3 Battery Backup Inverters

1.6 Statement of Research Problem

1.7 Aim and Objectives of the Study

1.7.1 Aim

1.7.2 Objectives

Chapter Two

Literature Review

2.1 Energy Sources

2.1.1 Non Renewable Energy Sources

2.1.2 Renewable Energy Sources

2.2 Solar Energy as Future

2.2.1 Pollution Free Energy

2.2.2 Reduction in Green House Gases

2.2.3 Energy Production on Remote Locations

2.3 Solar Inverter Parts

2.3.1 Solar Battery Charger

2.3.2 Solar Panel

2.3.3 Rechargeable Battery

2.3.4 Inverter

2.4 Modelling Of 50watt Solar Inverter

2.4.1 Selection of Battery Size and Solar Panel

Chapter Three

Methodology

3.1 Block Diagram of the System

3.2 System Operation with Block Diagram

3.3 Calculating the Load

3.4 Ratings of Solar Devices Used For the Construction

3.5 Testing Of Solar Panel Parameters

3.6 Solar Panel Array Connection

3.6.1 Solar Panels in Series connection

3.6.2 Solar Panel in Parallel Connection

3.7 Calculating the Size of Solar Panels to Supply the Load

3.7.1 Peak Sun Hours

3.8 Solar Panel Positioning

3.9 Direct Connection of Solar Panel

3.10 Connection with Charge Controller

3.11 Circuit Diagram of the Inverter

3.12 Components of the Inverter Circuit Diagram

3.12.1 Resistor

3.12.2 Capacitors

3.12.3 Diode

3.12.4 Transistor

3.12.5 Metal Oxide Semi-Conductor Field Effect Transistor (MOSFET)

3.13 The Battery

3.14 Transformer

3.15 E.M.F Equation of a Transformer

3.16 Determination of the Oscillating Frequency

3.17 Drain Current of the MOSFET

3.18 How to choose the best inverter battery

3.19 The Change Over

3.20 Inverter Ac Output

3.21 Protections

3.22 Indicators

3.23 Switch

3.23 Charge Controller Installation

Chapter Four

Results and Conclusion

4.1 Discussion of Results

4.1.1 Testing of the Inverter under load condition

4.1.2 Construction and connections

4.1.3 Cost Analysis

4.1.4 Troubleshooting/ Fault tracing

4.1.5 Maintenance and Repair

4.1.6 Findings

4.2 Conclusion

4.3 Contribution and Recommendation

4.3.1 Contribution

4.3.2 Recommendation

References

The demands for energy have been directly proportional to human population in recent years. Currently more than 80% of the world’s energy is obtained from fossil fuels, where coal is the dominant factor. Unavailability of the dominant contributor of fossil fuels in the nearest future and also pollution from fossil fuels which causes global warming, has led to a search for a cleaner, better and more efficient source of energy. Eventually, a new form of energy known as Solar Energy was discovered. In addition to being renewable, solar energy is also the cleanest form of energy. Solar photovoltaic energy implies a potential for directly taping the sun heating or generating electricity by harnessing the energy radiated from the sun. The only cost incurred in using solar photovoltaic energy is the equipment used in harnessing it. This research work presents a simplified design and construction of a photovoltaic solar system for harnessing the sun's energy. The solar inverter is more like the heart box of a solar photovoltaic system, because of its ability to convert the direct current coming from the solar panel to alternating current and has a sole responsibility to provide the desire power output suitable to run our various appliances. In this project, a 2KW 200-230 volts solar panel inverter at a frequency of 50Hz was designed and constructed. The device is constructed with locally sourced components and materials of regulated standard. The basic principle of its operation is a simple conversion of 12V DC from a battery using integrated circuits and semiconductors at a frequency of 50Hz, into a 230V AC across the windings of a transformer. A solar panel is used to charge the battery using a solar charge controller. This project (device) offers a better alternative to Public Power Supply, Generators as well as UPS, considering it is cost effective, noiseless and easy maintainability.

___________________ _________________

Dr. S. Ehika Date

Supervisor

___________________ _________________

Dr. R. O. Okanigbuan Date

Head of Department (Physics)

__________________ _________________

External Examiner Date

DEDICATION

This project work is dedicated to God Almighty for his unending love, grace, provision, protection, favour, mercies and wisdom upon my life throughout the course of this project. Also, I dedicate this work to my wonderful parents, Mr. & Mrs. Goddy Oahimire Akhere, who never gave up on me with their prayers, I am forever grateful.

ACKNOWLEDGMENT

I wish to express my profound gratitude to God Almighty for his love, grace, wisdom, protection and provision during the course of research and writing this project.

My profound gratitude goes to my supervisor, Dr. S. Ehika with whom my skills and potentials constantly advanced as he taught me to apply my skill to different range of subject areas and helped me organize my time effectively and think about the commercial viability of all that I learnt.

My special thanks go to the head of department (Physics), Dr. R. O. Okanigbuan and other academic staffs; Professor Emeritus J.E.A. Osemeikhian, Dr. G.K. Oyanna, Professor O. Ujuanbi, Professor Isaac Aigbedion, Professor S.E. Iyayi, Dr. S.I Jegede, Mr. S.O Salufu, Dr. O.J. Ataman, Mr. K.O. Ozegin, Dr.O.E. Akhirevbulu, Dr. A. Iyoha, Dr. C.V.O. Amadasun and Mrs. Anita Odeh; my special thanks goes to the Non-Academic Staff. You all contributed to my success, God bless you all.

To my exceptional parents, Mr. & Mrs. Goddy oahimire Akhere, my siblings, and My Uncle, Evang. & Mrs Akhabue Airiede Matthew, whose love and support sailed me through my days of academic exercise in this institution. I am sincerely grateful for your unquenchable love, endurance and support, God will continually bless and keep you.

Finally, to my friends, Mary, Jerry, Liberty, Samuel, Smart, David, John, Diana, Ugochukwu, Blessed, Maxwell, Darlington, Theophilus, Samson. who helped me with their resources to accomplish this task and others I could not mention due to space limitation, who might have contributed directly or indirectly to the successful completion of my program, I appreciate you all.

TABLE OF CONTENT

Title Page

Certification

Dedication

Acknowledgement

Table of Content

Abstract

Chapter One

Introduction

1.1 Solar Energy

1.2 Uses of Solar Energy

1.2.1 Heating

1.2.2 Cooling

1.2.3 Transportation

1.2.4 Generation of Electricity

1.3 Basic Principle of Solar Inverter

1.4 Need of Solar Inverter

1.5 Types of Solar Inverter

1.5.1 Stand Alone Inverters

1.5.2 Grid Tie Inverters

1.5.3 Battery Backup Inverters

1.6 Statement of Research Problem

1.7 Aim and Objectives of the Study

1.7.1 Aim

1.7.2 Objectives

Chapter Two

Literature Review

2.1 Energy Sources

2.1.1 Non Renewable Energy Sources

2.1.2 Renewable Energy Sources

2.2 Solar Energy as Future

2.2.1 Pollution Free Energy

2.2.2 Reduction in Green House Gases

2.2.3 Energy Production on Remote Locations

2.3 Solar Inverter Parts

2.3.1 Solar Battery Charger

2.3.2 Solar Panel

2.3.3 Rechargeable Battery

2.3.4 Inverter

2.4 Modelling Of 50watt Solar Inverter

2.4.1 Selection of Battery Size and Solar Panel

Chapter Three

Methodology

3.1 Block Diagram of the System

3.2 System Operation with Block Diagram

3.3 Calculating the Load

3.4 Ratings of Solar Devices Used For the Construction

3.5 Testing Of Solar Panel Parameters

3.6 Solar Panel Array Connection

3.6.1 Solar Panels in Series connection

3.6.2 Solar Panel in Parallel Connection

3.7 Calculating the Size of Solar Panels to Supply the Load

3.7.1 Peak Sun Hours

3.8 Solar Panel Positioning

3.9 Direct Connection of Solar Panel

3.10 Connection with Charge Controller

3.11 Circuit Diagram of the Inverter

3.12 Components of the Inverter Circuit Diagram

3.12.1 Resistor

3.12.2 Capacitors

3.12.3 Diode

3.12.4 Transistor

3.12.5 Metal Oxide Semi-Conductor Field Effect Transistor (MOSFET)

3.13 The Battery

3.14 Transformer

3.15 E.M.F Equation of a Transformer

3.16 Determination of the Oscillating Frequency

3.17 Drain Current of the MOSFET

3.18 How to choose the best inverter battery

3.19 The Change Over

3.20 Inverter Ac Output

3.21 Protections

3.22 Indicators

3.23 Switch

3.23 Charge Controller Installation

Chapter Four

Results and Conclusion

4.1 Discussion of Results

4.1.1 Testing of the Inverter under load condition

4.1.2 Construction and connections

4.1.3 Cost Analysis

4.1.4 Troubleshooting/ Fault tracing

4.1.5 Maintenance and Repair

4.1.6 Findings

4.2 Conclusion

4.3 Contribution and Recommendation

4.3.1 Contribution

4.3.2 Recommendation

References

ABSTRACT

The demands for energy have been directly proportional to human population in recent years. Currently more than 80% of the world’s energy is obtained from fossil fuels, where coal is the dominant factor. Unavailability of the dominant contributor of fossil fuels in the nearest future and also pollution from fossil fuels which causes global warming, has led to a search for a cleaner, better and more efficient source of energy. Eventually, a new form of energy known as Solar Energy was discovered. In addition to being renewable, solar energy is also the cleanest form of energy. Solar photovoltaic energy implies a potential for directly taping the sun heating or generating electricity by harnessing the energy radiated from the sun. The only cost incurred in using solar photovoltaic energy is the equipment used in harnessing it. This research work presents a simplified design and construction of a photovoltaic solar system for harnessing the sun's energy. The solar inverter is more like the heart box of a solar photovoltaic system, because of its ability to convert the direct current coming from the solar panel to alternating current and has a sole responsibility to provide the desire power output suitable to run our various appliances. In this project, a 2KW 200-230 volts solar panel inverter at a frequency of 50Hz was designed and constructed. The device is constructed with locally sourced components and materials of regulated standard. The basic principle of its operation is a simple conversion of 12V DC from a battery using integrated circuits and semiconductors at a frequency of 50Hz, into a 230V AC across the windings of a transformer. A solar panel is used to charge the battery using a solar charge controller. This project (device) offers a better alternative to Public Power Supply, Generators as well as UPS, considering it is cost effective, noiseless and easy maintainability.

CHAPTER ONE

INTRODUCTION

The use of efficient photovoltaic solar cells has

emerged as an important solution in energy conservation and demand side

management. Owing to their initial high costs, they have not been an attractive

alternative for users who are able to buy cheaper electrical energy from the utility

grid. However, they have been extensively used in pumping and air conditioning

in remote and isolated areas where utility power is not available or too

expensive to transport (Ożadowicz, 2017). Although solar cell prices have

decreased considerably during the last years due to new developments in the

film technology and the manufacturing process, PV arrays are still considered

rather expensive compared with the utility fossil fuel generated electricity

prices. After building such an expensive renewable energy system, the PV array

has to be operated at its highest conversion efficiency by continuously

utilizing the maximum available output of the array. The electrical system

powered by solar cells requires special design considerations because of the

varying nature of the solar power generated resulting from unpredictable

changes in weather conditions which affect the solar radiation level as well as

the cell operating temperature. The efficiency of a PV plant is affected mainly

by three factors: the efficiency of the PV panel (in commercial PV panels it is

between 8-15%). The efficiency of the inverter (95-98%) and the efficiency of

the maximum power point tracking algorithm (which is over 98%) (Agarwal et al.,

2014). Improving the efficiency of the PV panel and that of the inverter is not

easy as it depends on the technology available. It may require better

components, which can increase drastically the cost of the installation.

Instead, improving the tracking of the maximum power point with new control

algorithms is easier, not expensive and can be done even in plants which are

already in use by updating their control algorithms, which would lead to an

immediate increase in PV power generation and consequently a reduction in its

price. In practice, the voltage dependency on the irradiation is often

neglected. As the effect on both the current and voltage is positive, i.e. both

increase when the irradiation rises, the effect on the power is also positive.

More the irradiation, the more power is generated. PV panel manufacturers

provide in their data sheets the temperature coefficients, which are the

parameters that specify how the open circuit voltage, the short circuit current

and the maximum power vary when the temperature changes. As the effect of the

temperature on the current is really small, it is usually neglected.

1.1 SOLAR ENERGY

In today's climate of growing energy needs and

increasing environmental concern, alternatives to the use of non-renewable and

polluting fossil fuels have to be investigated. One such alternative is solar

energy.

Solar energy is quite simply the energy produced

directly by the sun and collected elsewhere, normally the Earth. The sun

creates its energy through a thermonuclear process that converts about

650,000,0001tons of hydrogen to helium every second. The process creates heat

and electromagnetic radiation. The heat remains in the sun and is instrumental

in maintaining the thermonuclear reaction. The electromagnetic radiation

(including visible light, infra-red light, and ultra-violet radiation) streams

out into space in all directions (Bill Rindom,

2014)

Only a very small fraction of the total radiation

produced reaches the Earth. The radiation that does reach the Earth is the

indirect source of nearly every type of energy used today. The exceptions are

geothermal energy, and nuclear fission and fusion. Even fossil fuels owe their

origins to the sun; they were once living plants and animals whose life was

dependent upon the sun.

Due to the nature of solar energy, two components are

required to have a functional solar energy generator. These two components are

a collector and a storage unit. The collector simply collects the radiation

that falls on it and converts a fraction of it to other forms of energy (either

electricity and heat or heat alone). The storage unit is required because of

the non-constant nature of solar energy; at certain times only a very small

amount of radiation will be received. At night or during heavy cloud cover, for

example, the amount of energy produced by the collector will be quite small.

The storage unit can hold the excess energy produced during the periods of

maximum productivity, and release it when the productivity drops. In practice,

a backup power supply is usually added, too, for the situations when the amount

of energy required is greater than both what is being produced and what is

stored in the container (Ovaska , 2010).

1.2 USES OF SOLAR ENERGY

People use energy for many things, but a few general

tasks consume most of the energy. These tasks include transportation, heating,

cooling, and the generation of electricity. Solar energy can be applied to all

four of these tasks with different levels of success.

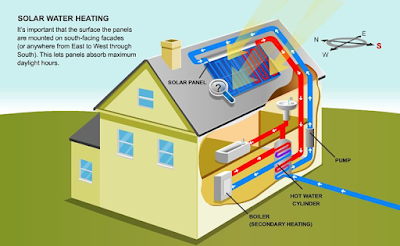

1.2.1 Heating

Heating is the business for which solar energy is best

suited. Solar heating requires almost no energy transformation, so it has a

very high efficiency. Heat energy can be stored in a liquid, such as water, or

in a packed bed. A packed bed is a container filled with small objects that can

hold heat (such as stones) with air space between them. Heat energy is also

often stored in phase-change or heat-of-fusion units. These devices will

utilize a chemical that changes phase from solid to liquid at a temperature

that can be produced by the solar collector. The energy of the collector is

used to change the chemical to its liquid phase, and is as a result stored in

the chemical itself. It can be tapped later by allowing the chemical to revert

to its solid form. Solar energy is frequently used in residential homes to heat

water. This is an easy application, as the desired end result (hot water) is

the storage facility. A hot water tank is filled with hot water during the day,

and drained as needed. This application is a very simple adjustment from the

normal fossil fuel water heaters.

Fig

1.1 – Heating Application of Solar Energy

1.2.2 Cooling

Solar energy can be used for other things besides

heating. It may seem strange, but one of the most common uses of solar energy

today is cooling. Solar cooling is far more expensive than solar heating, so it

is almost never seen in private homes. Solar energy is used to cool things by

phase changing a liquid to gas through heat, and then forcing the gas into a

lower pressure chamber. The temperature of a gas is related to the pressure

containing it, and all other things being held equal, the same gas under a

lower pressure will have a lower temperature. This cool gas will be used to

absorb heat from the area of interest and then be forced into a region of

higher pressure where the excess heat will be lost to the outside world. The

net effect is that of a pump moving heat from one area into another, and the

first is accordingly cooled.

Fig

1.2 – Cooling Through Solar Cell

1.2.3 Transportation

Of the main types of energy usage, the least suited to

solar power is transportation. While large, relatively slow vehicles like ships

could power themselves with large onboard solar panels, small constantly

turning vehicles like cars could not. The only possible way a car could be

completely solar powered would be through the use of battery that was charged

by solar power at some stationary point and then later loaded into the car.

Electric cars that are partially powered by solar energy are available now, but

it is unlikely that solar power will provide the world's transportation costs

in the near future.

1.2.4 Generation of Electricity

Besides being used for heating and cooling, solar

energy can be directly converted to electricity. Most of our tools are designed

to be driven by electricity, so if you can create electricity through solar

power, you can run almost anything with solar power. The solar collectors that

convert radiation into electricity can be either flat-plane collectors or

focusing collectors, and the silicon components of these collectors are

photovoltaic cells.

Fig

1.3 – Generation of Electricity From Solar Energy

Photovoltaic cells, by their very nature, convert

radiation to electricity. This phenomenon has been known for well over half a

century, but until recently the amounts of electricity generated were good for little

more than measuring radiation intensity. Most of the photovoltaic cells on the

market today operate at an efficiency of less than 15%; that is, of all the

radiation that falls upon them, less than 15% of it is converted to

electricity. The maximum theoretical efficiency for a photovoltaic cell is only

32.3%, but at this efficiency, solar electricity is very economical. Most of

our other forms of electricity generation are at a lower efficiency than this.

Unfortunately, reality still lags behind theory and a 15% efficiency is not

usually considered economical by most power companies, even if it is fine for

toys and pocket calculators. Hope for bulk solar electricity should not be

abandoned, however, for recent scientific advances have created a solar cell

with an efficiency of 28.2% efficiency in the laboratory. This type of cell has

yet to be field tested. If it maintains its efficiency in the uncontrolled

environment of the outside world, and if it does not have a tendency to break

down, it will be economical for power companies to build solar power facilities

after all.

Now, we know that solar panel transfers electrons into

DC, and most appliance at home is using AC, that's why we use inverters.

1.3 BASIC PRINCIPLE OF SOLAR INVERTER

A solar inverter, or PV inverter, converts the

variable direct current (DC) output of a photovoltaic (PV) solar panel into a

utility frequency alternating current (AC) that can be fed into a commercial

electrical grid or used by a local, off-grid electrical network. It is a

critical component in a photovoltaic system, allowing the use of ordinary

commercial appliances. Solar inverters have special functions adapted for use

with photovoltaic arrays, including maximum power point tracking and

anti-islanding protection

1.4 NEED OF SOLAR INVERTER

There are two types of sources for electrical power

generation. One is conventional and other is non- conventional. Today to

generate most of electrical power conventional sources like coal, gas, nuclear

power generators are used. Some of conventional source are polluted the

environment to generate the electricity. And nuclear energy is not much

preferable because of its harmful radiation effect on the mankind. After some

of ten years conventional sources will not sufficient enough to fulfill the

requirements of the mankind. So some of the electrical power should be

generated by non-conventional energy sources like solar, wind .With the

continuously reducing the cost of PV power generation and the further

intensification of energy crisis, PV power generation technology obtains more

and more application.

Conventionally, there are two ways in which electrical

power is transmitted. Direct current (DC) comes from a source of constant

voltage and is suited to short-range or device level transmission. Alternating

current (AC) power consists of a sinusoidal voltage source in which a

continuously changing voltage (and current) can be used to employ magnetic

components. Long distance electrical transmission favors AC power, since the

voltage can be boosted easily with the use of transformers. By boosting the

voltage, less current is needed to deliver a given amount of power to a load,

reducing the resistive loss through conductors.

The adoption of AC power has created a trend where

most devices adapt AC power from an outlet into DC power for use by the device.

However, AC power is not always available and the need for mobility and

simplicity has given batteries an advantage in portable power. Thus, for

portable AC power, inverters are needed. Inverters take a DC voltage from a

battery or a solar panel as input, and convert it into an AC voltage output.

Fig

1.4 – Solar Inverter Schematics

1.5 TYPES OF SOLAR INVERTER

Solar inverters may be classified into three broad

types.

1.

Stand Alone Inverters

2.

Grid Tie Inverters

3.

Battery Backup Inverters

1.5.1 Stand Alone Inverters

Stand-alone inverters, used in isolated systems where

the inverter draws its DC energy from batteries charged by photovoltaic arrays.

Many stand-alone inverters also incorporate integral battery chargers to

replenish the battery from an AC source, when available. Normally these do not

interface in any way with the utility grid, and as such, are not required to

have anti-islanding protection.

1.5.2 Grid Tie Inverters

Grid-tie inverters, which match phase with a

utility-supplied sine wave. Grid-tie inverters are designed to shut down

automatically upon loss of utility supply, for safety reasons. They do not

provide backup power during utility outages.

1.5.3 Battery Backup Inverters

Battery backup inverters, are special inverters which

are designed to draw energy from a battery, manage the battery charge via an

onboard charger, and export excess energy to the utility grid. These inverters

are capable of supplying AC energy to selected loads during a utility outage,

and are required to have anti-islanding protection.

1.6 STATEMENT OF RESEARH PROBLEM

The world demand for electric energy is constantly

increasing, and conventional energy resources are diminishing and are even

threatened to be depleted (Owusu, 2016). Moreover; their prices are rising. For

these reasons, the need for alternative energy sources has become

indispensable, and solar energy in particular has proved to be a very promising

alternative because of its availability and pollution-free nature. Due to the

increasing efficiencies and decreasing cost of photovoltaic cells and the

improvement of the switching technology used for power conversion, our goal is

to design an inverter powered by PV panels and that could supply stand-alone AC

loads. Solar panels produce direct currents (DC), and to connect these panels

to the electricity grid or use them in other industrial applications, we should

have an AC output at a certain required voltage level and frequency. The

conversion from DC to AC is essentially accomplished by means of a DC-AC

inverter, which is the major component in the system. Yet, the output of the

solar panels is not continuously constant and is related to the instantaneous

sunlight intensity and ambient temperature.

1.7 AIM AND OBJECTIVES OF THE STUDY

The aim of this study is to study the solar inverter

and the various ways it works. The objectives of the study are as follow;

1) To study the sun in details;

2) To study the solar energy and panel in details,

3) To study the construction and the working mechanisms

of solar inverters.

CHAPTER TWO

LITERATURE

REVIEW

Photovoltaic, also called solar cells, are electronic

devices that convert sunlight directly into electricity. Photovoltaic power

were first discovered by a French scientist Edmond Becquerel in 1839. The first

working solar cell was successfully made by Charles fritts in 1882. It was made

of thin sheets of selenium and coated with gold. The use of solar panels for

generating electricity and heat seems relatively like new development, it has

actually been widely used to generate power since early 1900‟s. In 1954 Bell

laboratory mass produced the first crystal silicon solar cell. The bell PV

converted 4% of the sun’s energy into electricity a rate that was considered

the cutting edge in energy technology. Heir scientists Daryl M. Chapin et al

made a silicon-based solar cell with an efficiency of about 6% (Chapin et al.,

1954). Scientists continued to reinvent and enhanced on the design of the

original solar cell and were able to produce a solar cell that was capable of

putting 20% return electricity rate. In the late 1900’s as awareness grew in

the science community about the effects of global warming and the need for

renewable energy sources, scientists continued to refine the silicon PV and by

early 2000 they were able to make a solar cell with 24% electricity return. In

just seven years scientists were again able to increase the electricity return

of silicon solar cell using space age materials. By 2007, modern silicon PV Solar

cells were operating with 28% electricity return. There are a wide range of PV

cell technologies on the market today and more applications.

In 1953, an article in a magazine with a title “Why

Don’t We Have. Sun Power” with a statement “Every hour, it floods the earth

with a deluge of thermal energy equal to 21 billion tons of coal”. In fact

according to latest figures published, the surface of the earth receives about

124 exa (1018) Watts or 3,850 zetta (1024) Joules per

year of solar power (George, 2009). The spectrum of the solar light coming from

sun covers from about 250 nm to about 2500 nm in wavelength. By the way visible

light of human beings covers from 400 to 700 nm, at which band the light is

very dense, about 1.5 W/m2/nm at 400 nm, going up to about 1.75 W/m2/nm

at about 550 nm and then comes back to 1.5 W/m2/nm at 700 nm as can be deduced

from the figure. Solar thermal heating is the result of the whole solar

spectrum, for this reason, even white painted cars, get hot, because though

most of the visible light is reflected, but the other parts of the spectrum,

heats the car. Though mirrors reflect most of the wide spectrum of sun, but the

glass covering the mirror, gets hot. There are two methods for converting solar

power into electricity, thermal which is based on concentrating solar power by

mirrors or other type of reflectors to produce high temperature to generate

water vapour or other liquids with high pressure to rotate turbines to generate

electricity or by making use of photovoltaic (PV) effect to convert solar power

to electric power directly. A photovoltaic complete system usually consists of

the followings: Photovoltaic units, batteries, charging controllers, inverters,

load controllers, circuit breakers and wiring.

Renewable energy systems (REN) are distinguished to

various natural renewable energy resources (RER) such as sunlight, wind, rain,

tides, and geothermal heat, which are naturally replenished. According to

Greenpeace International, about 18% of global electricity generation comes from

renewables in 2010 (Jay 2010). The 18% share of renewables in electricity

generation is divided into 15% of global electricity coming from

hydroelectricity and 3% from new renewables. Nevertheless, the energy

revolution scenario demonstrates how by 2020 an impressive 32% of global

electricity needs can be met by renewable energy [Greenpeace International,

2010). However, the global target for

new renewable energy is 20% by 2020, whereas the proposed target of UK is 15%

(HOUSE OF LORDS, 2008). Established

technologies such as wind and solar take the early front, but rapidly emerging

technologies such as concentrating solar thermal, geothermal and ocean energy,

all contribute to 2020 energy mix. However, this project focuses on the

exploitation of solar panel.

A solar inverter or PV inverter, is a type of

electrical converter which converts the variable direct current (DC) output of

a photovoltaic (PV) solar panel into a utility frequency alternating current

(AC) that can be fed into a commercial electrical grid or used by a local,

off-grid electrical network. It is a critical balance of system (BOS)–component

in a photovoltaic system, allowing the use of ordinary AC-powered equipment.

Solar power inverters have special functions adapted for use with photovoltaic

arrays, including maximum power point tracking and antiislanding protection.

Solar inverters use maximum power point tracking

(MPPT) to get the maximum possible power from the PV array. Solar cells have a

complex relationship between solar irradiation, temperature and total

resistance that produces a non-linear output efficiency known as the I-V curve.

It is the purpose of the MPPT system to sample the output of the cells and

determine a resistance (load) to obtain maximum power for any given

environmental conditions. The fill factor, more commonly known by its

abbreviation FF, is a parameter which, in conjunction with the open circuit

voltage (Voc ) and short circuit current (Isc ) of the panel, determines the

maximum power from a solar cell. Fill factor is defined as the ratio of the

maximum power from the solar cell to the product of Voc and Isc (Benanti et al., 2005). There are three main

types of MPPT algorithms: perturb-and-observe, incremental conductance and

constant voltage. The first two methods are often referred to as hill climbing

methods; they rely on the curve of power plotted against voltage rising to the

left of the maximum power point, and falling on the right (Hohm, et al., 2003).

Solar micro-inverter is an inverter designed to operate with a single PV

module.

The micro-inverter converts the direct current output

from each panel into alternating current. Its design allows parallel connection

of multiple, independent units in a modular way. Micro-inverter advantages

include single panel power optimization, independent operation of each panel,

plug-and play installation, improved installation and fire safety, minimized

costs with system design and stock minimization. A 2011 study at Appalachian

State University reports that individual integrated inverter setup yielded

about 20% more power in unshaded conditions and 27% more power in shaded

conditions compared to string connected setup using one inverter. Both setups

used identical solar panels. Solar grid-tie inverters are designed to quickly

disconnect from the grid if the utility grid goes down. This is an NEC

requirement that ensures that in the event of a blackout, the grid tie inverter

will shut down to prevent the energy it produces from harming any line workers

who are sent to fix the power grid. Grid-tie inverters that are available on

the market today use a number of different technologies. The inverters may use

the newer high-frequency transformers, conventional low-frequency transformers,

or no transformer. Instead of converting direct current directly to 120 or 240

volts AC, high-frequency transformers employ a computerized multi-step process

that involves converting the power to high-frequency AC and then back to DC and

then to the final AC output voltage. Historically, there have been concerns

about having transformerless electrical systems feed into the public utility

grid. The concerns stem from the fact that there is a lack of galvanic

isolation between the DC and AC circuits, which could allow the passage of

dangerous DC faults to the AC side ( Fraunhofe, 2014). Since 2005, the NFPA's

NEC allows transformer-less (or non-galvanically) inverters. The VDE 0126-1-1

and IEC 6210 also have been amended to allow and define the safety mechanisms

needed for such systems. Primarily, residual or ground current detection is

used to detect possible fault conditions. Also isolation tests are performed to

ensure DC to AC separation. Maximum power point tracking Solar micro-inverters

A solar micro-inverter in the process of being installed. The ground wire is

attached to the lug and the panel's DC connections are attached to the cables

on the lower right.

The AC parallel trunk cable runs at the top Grid tied

solar inverters (just visible). Many solar inverters are designed to be connected

to a utility grid, and will not operate when they do not detect the presence of

the grid. They contain special circuitry to precisely match the voltage,

frequency and phase of the grid. Advanced solar pumping inverters convert DC

voltage from the solar array into AC voltage to drive submersible pumps

directly without the need for batteries or other energy storage devices. By

utilizing MPPT (maximum power point tracking), solar pumping inverters regulate

output frequency to control the speed of the pumps in order to save the pump

motor from damage. Solar pumping inverters usually have multiple ports to allow

the input of DC current generated by PV arrays, one port to allow the output of

AC voltage, and a further port for input from a water-level sensor.

2.1 ENERGY SOURCES

An energy resource is something that can produce heat,

power life, move objects, or produce electricity. Matter that stores energy is

called a fuel. Human energy consumption has grown steadily throughout human

history.

There are two type of energy sources

1) Non Renewable Energy Sources

2) Renewable Energy Sources

2.1.1 Non Renewable Energy Sources

Non-renewable energy comes from sources that will run

out or will not be replenished in our lifetimes—or even in many, many

lifetimes. Most non-renewable energy sources are fossil fuels: coal, petroleum,

and natural gas. Carbon is the main element in fossil fuels.

2.1.2 Renewable Energy Sources

Wind, solar, and biomass are three emerging renewable

sources of energy. Renewable energy is generally defined as energy that is

collected from resources which are naturally replenished on a human timescale,

such as sunlight, wind, rain, tides, waves, and geothermal heat.

2.2 SOLAR ENERGY AS FUTURE

Solar

power has two big advantages over fossil fuels. The first is in the fact that

it is renewable; it is never going to run out. The second is its effect on the

environment.

2.2.1 Pollution Free Energy

While the burning of fossil fuels introduces many

harmful pollutants into the atmosphere and contributes to environmental

problems like global warming and acid rain, solar energy is completely

non-polluting. While many acres of land must be destroyed to feed a fossil fuel

energy plant its required fuel, the only land that must be destroyed for a

solar energy plant is the land that it stands on. Indeed, if a solar energy

system were incorporated into every business and dwelling, no land would have

to be destroyed in the name of energy. This ability to decentralize solar

energy is something that fossil fuel burning cannot match.

2.2.2 Reduction in Green House Gases

Global warming and energy policies have become a hot

topic on the international agenda in the last years. Developed countries are

trying to reduce their greenhouse gas emissions. For example, the European

Union has committed to reduce their greenhouse gas to at least 20% below 1990

levels and to produce no less than 20% of its energy consumption from renewable

sources by 2020. In this context, photovoltaic (PV) power generation has an

important role to play due to the fact that it is a green source. The only

emissions associated with PV power generation are those from the production of

its components. After their installation they generate electricity from the

solar irradiation without emitting greenhouse gases. In their life time, PV

panels produce more energy than that for their manufacturing. Also, they can be

installed in places with no other use, such as roofs and deserts.

2.2.3 Energy Production on Remote

Locations

They can produce electricity for remote locations,

where there is no electricity network. The latter type of installations is

known as off-grid facilities and sometimes they are the most economical

alternative to provide electricity in isolated areas. However, most of the PV

power generation comes from grid-connected installations, where the power is

fed in the electricity network. In fact, it is a growing business in developed

countries such as Germany which is world leader in PV power generation followed

by Spain, Japan, USA and Italy.

As the primary element of construction of solar

panels, silicon, is the second most common element on the planet, there is very

little environmental disturbance caused by the creation of solar panels. In

fact, solar energy only causes environmental disruption if it is centralized

and produced on a gigantic scale. Solar power certainly can be produced on a

gigantic scale, too. Among the renewable resources, only in solar power do we

find the potential for an energy source capable of supplying more energy than

is used.

Fig

2.1 – Electricty Generation From Remote Locations

Suppose that of the 4.5x1017 kWh per annum that is

used by the earth to evaporate water from the oceans we were to acquire just

0.1% or 4.5x1014 kWh per annum. Dividing by the hours in the year gives a

continuous yield of 2.90x1010 kW. This would supply 2.4 kW to 12.1 billion

people. This translates to roughly the amount of energy used today by the

average person available to over twelve billion people. Since this is greater

than the estimated carrying capacity of the Earth, this would be enough energy

to supply the entire planet regardless of the population. Unfortunately, at

this scale, the production of solar energy would have some unpredictable

negative environmental effects. If all the solar collectors were placed in one

or just a few areas, they would probably have large effects on the local

environment, and possibly have large effects on the world environment.

Everything from changes in local rain conditions to another Ice Age has been predicted

as a result of producing solar energy on this scale. The problem lies in the

change of temperature and humidity near a solar panel; if the energy producing

panels are kept non-centralized, they should not create the same local, mass

temperature change that could have such bad effects on the environment. Of all

the energy sources available, solar has perhaps the most promise. Numerically,

it is capable of producing the raw power required to satisfy the entire

planet's energy needs. Environmentally, it is one of the least destructive of

all the sources of energy. Practically, it can be adjusted to power nearly

everything except transportation with very little adjustment, and even

transportation with some modest modifications to the current general system of

travel. Clearly, solar energy is a resource of the future.

Fig 2.2 – Role of Solar Energy In Renewable

Energy Consumption

2.3 SOLAR INVERTER PARTS

There are few sections of the solar inverter they are:

1) The solar battery recharger,

2) The solar panel

3) Rechargeable battery

4) The inverter.

2.3.1 Solar Battery Charger

A battery charger is a device used to put energy into

a secondary cell or (rechargeable) battery by forcing an electric current

through it. The charge current depends upon the technology and capacity of the

battery being charged. For example, the current that should be applied to

recharge a 12 V car battery will be very different from the current for a

mobile phone battery

The solar battery recharger as the name suggest it is

in fact a battery charger which charges a sealed rechargeable battery of 6V 4.5

AH in this case. The solar battery charger derives its power from the12V 500mA

solar panel. The solar panel which in turn converts the sunlight to electrical

energy. The charger converts the raw 12V from the solar panel to a regulated

voltage feed for the sealed rechargeable battery.

1) The solar battery recharger features:

2) Custom controllable voltage regulation.

3) Auto cut-off when battery is fully charged.

4) Filtered input from the solar panel.

5) No current back flows from the battery.

6) Very simple, compact and efficient.

2.3.2 Solar Panel

A

solar panel (also solar module, photovoltaic module or photovoltaic panel) is a

packaged, connected assembly of solar cells, also known as photovoltaic cells.

The solar panel can be used as a component of a larger photovoltaic system to

generate and supply electricity in commercial and residential applications.

Because

a single solar panel can produce only a limited amount of power, many

installations contain several panels. A photovoltaic system typically includes

an array of solar panels, an inverter, and sometimes a battery and

interconnection wiring.

Fig

2.7 – Solar Panel

Solar panels use light energy (photons) from the sun

to generate electricity through the photovoltaic effect. The structural (load

carrying) member of a module can either be the top layer or the back layer. The

majority of modules use wafer- based crystalline silicon cells or thin-film

cells based on cadmium telluride or silicon. The conducting wires that take the

current off the panels may contain silver, copper or other non-magnetic

conductive transition metals.

The cells must be connected electrically to one

another and to the rest of the system. Cells must also be protected from

mechanical damage and moisture. Most solar panels are rigid, but semi-flexible

ones are available, based on thin-film cells.

Electrical connections are made in series to achieve a

desired output voltage and/or in parallel to provide a desired current

capability (Fitzgerald, 2010). Separate diodes may be needed to avoid reverse

currents, in case of partial or total shading, and at night. The p-n junctions

of mono-crystalline silicon cells may have adequate reverse current

characteristics that these are not necessary. Reverse currents waste power and

can also lead to overheating of shaded cells. Solar cells become less efficient

at higher temperatures and installers try to provide good ventilation behind

solar panels.

Some recent solar panel designs include concentrators

in which light is focused by lenses or mirrors onto an array of smaller cells.

This enables the use of cells with a high cost per unit area (such as gallium

arsenide) in a cost-effective way.

Depending on construction, photovoltaic panels can

produce electricity from a range of frequencies of light, but usually cannot

cover the entire solar range (specifically, ultraviolet, infrared and low or

diffused light). Hence much of the incident sunlight energy is wasted by solar

panels, and they can give far higher efficiencies if illuminated with

monochromatic light. Therefore, another design concept is to split the light

into different wavelength ranges and direct the beams onto different cells

tuned to those ranges. This has been projected to be capable of raising efficiency

by 50%.

Currently the best achieved sunlight conversion rate

(solar panel efficiency) is around 21% in commercial products, typically lower

than the efficiencies of their cells in isolation. The energy density of a

solar panel is the efficiency described in terms of peak power output per unit

of surface area, commonly expressed in units of watts per square foot (W/ft2).

The most efficient mass-produced solar panels have energy density values of

greater than 13 W/ft2 (140 W/m2).

2.3.3 Rechargable Battery

The battery used in this project is a rechargeable

sealed lead sulphate battery rating 12V 4.5AH. This type of battery is

excellent for rechargeable purpose A rechargeable battery or storage battery is

a group of one or more electrochemical cells. They are known as secondary cells

because their electrochemical reactions are electrically reversible.

Rechargeable batteries come in many different shapes and sizes, ranging

anything from a button cell to megawatt systems connected to stabilize an electrical

distribution network. Several different combinations of chemicals are commonly

used, including: lead–acid, nickel cadmium (NiCd), nickel metal hydride

(NiMH),lithium ion (Li-ion), and lithium ion polymer (Li-ion polymer).

Fig 2.8 – Rechargable Battery

Rechargeable batteries have lower total cost of use and environmental impact than disposable batteries. Some rechargeable battery types are available in the same sizes as disposable types. Rechargeable batteries have higher initial cost, but can be recharged very cheaply and used many times.

2.4.4 Inverter

Since normal dc can’t be used in most applications due to which there is a requirement that somehow the dc is changed to ac for this the inverter is used which converts the dc to ac of suitable range for use in house hold appliances.

In this project the dc from the sealed rechargeable battery of 6V is fed to the inverter which then converts it to ac of 140V – 220V this makes it possible to recharge normal mobile chargers (Gupta, 2009).

An inverter is an electrical device that converts direct current (DC) to alternating current (AC), the converted AC can be at any required voltage and frequency with the use of appropriate transformers, switching, and control circuits.

Solid-state inverters have no moving parts and are used in a wide range of applications, from small switching power supplies in computers, to large electric utility high-voltage direct current applications that transport bulk power. Inverters are commonly used to supply AC power from DC sources such as solar panels or batteries. The inverter performs the opposite function of a rectifier.

2.4 MODELLING OF 50WATT SOLAR INVERTER

A successful design involves accurate knowledge of daily electrical load calculation and accounts for all worst case scenarios which might possibly occur during operation. A good designer will be pragmatic and keep the costs down by cutting on unnecessary over sizing the system.

2.4.1 Selection of Battery Size and Solar Panel

Now let’s begin, suppose we have to design an inverter for load of 40 Watts and required backup time for batteries is 1 Hour and we have to model a Solar Inverter than Inverter ratings, Required No of Solar Panel and No of batteries are calculated as follows.

Inverter should be greater 25% than the total Load

40 x (25/100) = 10

40+10 = 50 Watts

This is the rating of the UPS (Inverter)

Now the required Back up Time in Hours = 2.5 Hours

Suppose we are going to install 4.5Ah, 6 batteries,

Now for One Battery (i.e. the Backup time of one battery)

27Wh / 40W = 0.675 Hours

But our required Backup time is 1 Hour.

Therefore, 1/0.675 = 2→ i.e. we will now connect two batteries each of 4.5Ah, 6V this is a 12 V inverter system, now we will install two batteries (each of 6V, 4.5Ah) in Parallel. Because this is a 6V inverter System, so if we connect these batteries in parallel, then the Voltage of batteries 6V remains same, while it’s Ah (Ampere Hour) rating will be increase.

1) In parallel Connection, Voltage will be same in each wire or section, while current will be different i.e. current is additive e.g. I1+I2+I3…+In = 4.5Ah +4.5Ah = 9Ah.

2) In Series Circuits, Current is same in each wire or section while voltage is different i.e. Voltage is additive e.g.V1+V2+V3….Vn. For The above system if we connect these batteries in series instead of parallel, then The rating of batteries become V1+V2 = 12V while the current rating would be same i.e. 4.5Ah.

3) We will now connect 2 batteries in parallel (each of 4.5Ah, 6V), therefore for two Batteries it will be 9 Ah 6V, Now Required Charging Current for these two batteries (Charging current should be 1/10 of batteries Ah) → 9Ah x (1/10) = 0.9A

Now the required No of Solar Panels

P = VI

P = 6V x 0.9 A

P = 5.4 Watts

This is our required watts for solar panel (only for battery charging, and then battery will supply power to the load), Now

5.4W/3W = 2 Solar panels

Or 5.4W/6 = 1 Solar panels.

CHAPTER THREE

METHODOLOGY

3.1 Block Diagram of the System

Figure 3.1 shows the solar system working diagram

3.2 System Operation with Block Diagram

The solar panel absorbs energy produced by the sun and converts it into electrical energy. It does this by absorbing the sun rays into the modules of the solar panel hence produced free electrical charge carriers in the conduction and valence bands. The electricity produced by the solar panel was then transferred to the charge controller as shown in fig 3.1 above. The charge controller regulates the rate at which electric current goes in and out of the battery. It turns off charge when the battery reaches the optimum charging point and turns it on when it goes below a certain level. It fully charges the battery without permitting overcharge. The regulated voltage from the charge controller was then transferred to the solar battery. The batteries were the key component in this solar power system. It provided energy storage for the system. The energy stored in the batteries was then used to power the load but it was first converted to AC voltage by the use of an inverter due to they were AC loads. The photovoltaic ally produced direct current was commuted periodically by controlled oscillatory system and feed to power electronic semiconductor switches such as transistors which were connected the power transformer. Here the voltage was stepped up to the desired ac voltage. The inverter could also charge the battery when there is public power supply.

3.3 Calculating the load

In other to determine the power use of each appliance and how long they will be operated, the appliance datasheets or nameplates should be checked. If their consumption is in amps, multiply by their voltage to yield their power. If they are AC loads driven by an inverter, multiply the power by 1.1 to take into account the losses in the inverter. To calculate the total Watt hour (Wh) consumed in a 24hr period. Multiply the power consumption of the appliance by the number of hours it runs per day and sum together with all the other appliances. As an example – a large fridge that is rated at an average of 2.1A at 12V, a small fridge used as a freezer rated at 1A at 12V (double the rated current use when used as a freezer – 2A instead of 1A), an LED light rated at 0.5A at 12V that operates for a couple of hours per day, and an AC television rated at 180W used for a couple of hours per day.

Large fridge (Wh):2.1 × 12 × 24 = 605𝑊ℎ

Freezer (Wh): 2 × 12 × 24 = 576𝑊ℎ

LED Light (Wh): 0.5 × 12 × 2 = 12𝑊ℎ

TV (Wh):180 × 1.1 × 2 = 396

Total energy consumption over 24hr period: 605 + 576 + 12 + 396 = 1589Wh

3.3 Ratings of solar devices used for the construction

The rating of the devices used in the solar system is as important as the calculation of the load, it tells you or give you an insight of what the device is capable of doing in a solar system. The rating of power in a solar panel is often given in “watt peak” (WP), which means that a solar panel rated 100WP reaches its peak power output of 100w when placed under the sun. The rating of the voltage and current isn’t different as this give rise to the total power output.

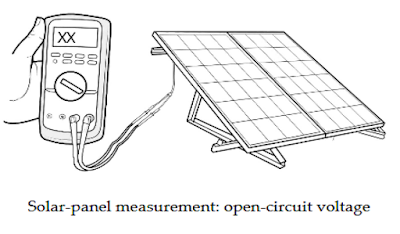

3.4 Testing of Solar Panel Parameters

When a solar panel is manufactured, it is tested to ensure it meets the required standards. There are two important parameters to be considered during testing;

1. The short circuit current (ISC), which is the current measured when the solar panel terminals

(positive and negative) are connected together and there is no load.

2. The open circuit voltage (VOC). Which is the voltage across the negative and negative

terminals of the solar panel when it is not connected to any load.

Fig 3.3 shows a solar panel voltage being tested with a multimeter

3.5 Solar Panel Array Connection

Connecting identical solar panels in an array for example, if you have three solar panels that are rated at 100wp and they are to be connected either in series or parallel combinations, the total power from the array is the sum of the power rating of each individual solar panel. Interconnecting solar panels to form an array can be done in three different ways. They are done either in;

i. Series connections to increase the output voltage of the solar panel array.

ii. Parallel connections to increase the output current of the solar panel array.

iii. series-parallel connections to increase both the output voltage and the current of a solar panel array.

Figure 3.4 shows a group of solar panel connected

together to form a solar array

3.5.1 Solar Panels in Series connection

When

identical solar panels (solar panels having the same parameters) are connected

in series, they produce a higher output voltage. This increased output voltage

is the sum of voltages on the individual solar panels. To connect solar panels

in series, the positive (+) terminal of a solar panel is connected to the

negative (-) terminal of the next solar panel in the array. Imagine you have

three solar panels, each with 12V and 9A, connected in series. The output

current and voltage of this array will then be 36V/9A, respectively. See figure

3.5.

Figure 3.5 shows identical solar panel connected in

series

3.5.2 Solar Panel in Parallel Connection

When identical solar

panels are connected in parallel, they achieve a higher output current. This

increased output current is the sum of current on the individual solar panels.

To connect solar panels in parallel, the positive (+) terminal of a solar panel

is connected to the (+) terminal of the next solar panel in the array.

Figure 3.6 shows identical solar panels connected in parallel

3.4 Calculating the Size of Solar Panels to Supply the Load

The size of solar panels you need is the energy consumption in a 24hr period divided by the number of hours in a day that the solar panels produce energy for. For number of hours, we use peak sun hours which is explained below. If we assume we are in a sunny area with 8 peak sun hours per day we get:

Solar Panel Rating = 1589 / 8 = 199W

So in this case you need around 199W of solar panels. What if it’s cloudy? What if your panels are dirty? What if your panels are not faced directly at the sun and at the correct angle? What if you leave the lights on longer than calculated? What about the loss in panel efficiency with elevated temperatures? What about loss in panel efficiency as they age? What about the fact that the regulator is not 100% efficient? What about the variation in load from the fridges depending on ambient temperature? What about variations in irradiation due to season?? What if, at the same time, I want to chill a carton of warm coca cola, charge a laptop and charge a torch? So the equation would become incredibly complicated if you were to try to work it all out. You need to multiply by a fudge factor. The fudge factor is a number anywhere between 1 and infinity. It’s simply down to probability of running out of power. Assuming you run your system 24 hours a day, 365 days a year, if your fudge factor is 1, then you might run out of power most of the time. There is no way to guarantee power; you are simply shifting the probability. If you are powering life critical systems your fudge factor might be 10 or more. A typical fudge factor might be say 1.2. So in our example it changes:

Solar Panel Rating = (1589 ÷ 8) × 1.2 = 238W

3.4.1 Peak Sun Hours

‘Peak sun hours’ is a way to standardize how much sunlight a particular area receives at a particular time of year. It’s the equivalent number of hours per day when solar irradiation averages 1000 watts per square meter. The units are kWh per square meter per day. I used 8 hours in the calculation above. Peak sun hours for many places in Nigeria during dry season is around 8 hours. Some places it is more, some places it is less. Eight is a reasonable estimate for Nigeria in dry season. What about wet season? In northern cities we might expect 2 to 3 peak sun hours during wet season. In south west in wet season we could be around 1.5 to 2 peak sun hours per day. So we can see there is a lot of variation depending on location and season. This has to be taken into account when sizing the panels. If the above system needed to work in south-west in the middle of wet season, then using the same 1.2 fudge factor, the calculation would be:

(1589 ÷ 1.5) × 1.2 = 1271W

So we would need around 8 x 130W panels.

3.5 Solar Panel Positioning

The solar panels should be pointed directly to the sun, perpendicular to the sun’s rays. If there are multiple panels then it is suggested that they should all be positioned the same direction. Actually each panel individually should be positioned as close as perfectly perpendicular to the sun’s rays as possible regardless of the position of the other panels. The voltage versus current relationship and the resistance in the electrical distribution will allow the better positioned solar panels to provide more energy even if it’s not as much as when all panels are ideally positioned. Of course the maximum energy is obtained when all panels are ideally positioned in which case they will all be positioned the same.

3.5.1 Connecting Your Solar Panels – Direct Connection

You can connect the solar panels directly to the auxiliary battery. This is the simplest system but it’s quite a poor arrangement. There is potential to overcharge and damage your battery. A solar panel will continue to charge to its open circuit voltage, which is usually around 17.5V for panels used in 12V systems. This is much too high for lead acid batteries and will cause excessive grid corrosion and pressure venting and damage of the battery. Small panels will still lead to the overcharge condition, it will just take longer. Another negative aspect to this arrangement is that the solar panel is not allowed to operate at its optimal voltage. The voltage is clamped to whatever the battery voltage is. So the solar panel will not be able to achieve its rated power output and it will take longer to charge your battery.

Figure 3.7 schematic diagram of solar panel connected to the battery

3.6 Solar charge Controller/Regulator

To overcome the limitations of a direct solar panel connection to your auxiliary battery, a solar regulator is used. Some solar panels come with an integrated solar regulator. Some dual battery isolator and DC-DC converter vendors also provide solutions for solar charging and distribution. For the purpose of this project, I used a separate third party solar regulator. Solar regulators charge the battery according to an optimized charging profile, reducing grid corrosion and will terminate the charge at the correct voltage. The best solar regulators are of the type Maximum Power Point Tracking (MPPT). These regulators load the solar panels according to their optimized current and voltage characteristics for the given level of irradiation. This ensures your solar panels are operating as efficiently as possible, providing you with the most energy and highest charge rate possible. MPPT solar regulators are the best solution for connecting solar panels. To size the solar regulator, sum the total power output of all the panels together and divide by 12 to give you a current rating. The solar regulator needs to exceed this value. So for a 100W solar panel that I am using, the current would be

100/12=8.33A (The rating of the solar regulator needs to exceed this).

Figure 3.8 schematic diagram of solar panel connected to the battery with solar regulator

CIRCULT DIAGRAM OF THE INVERTER

Figure 3.4 Show the complete circuit diagram of the 12V-DC-220V-AC solar panel inverter

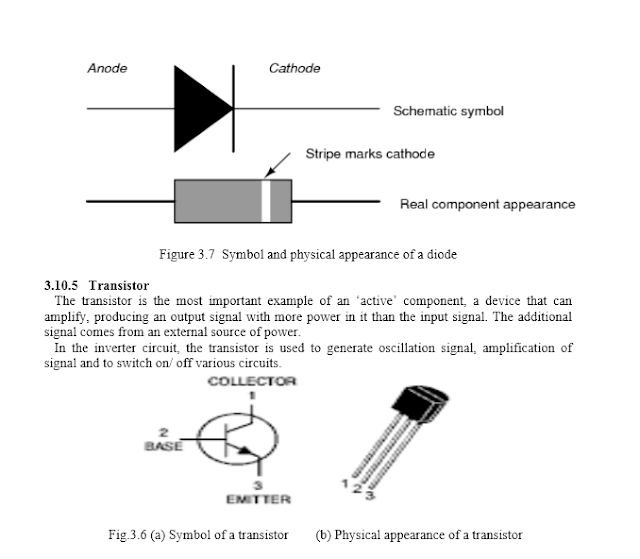

3.10 Components of the inverter circuit diagram and their functions in the circuit

One of the purposes of this chapter is to highlight the various components used in the construction of the circuits that makes up the project as well as outlining whatever calculation involved where necessary. The components making up the inverter include relays, resistors, capacitors, transistors, voltage regulators, heat sink, MOSFETs, switch and various ICs etc.

3.10.1 Resistor

The resistor used in this circuit are six (6) in numbers, they are 300ohms (R1), 1K (R2), 220ohms (R3), 220ohms (R4), 390k (R5) and 1k (R6). Resistors are the most widely used circuit element. It offer opposition or introduces resistance to the flow of charges (electrons) or current in an electric circuit. They are placed to regulate the flow of current and voltage drop in both electrical and electronic circuits. In power circuits, they are used to reduce voltage by dissipating power.

3.10.6 Metal Oxide Semi-Conductor Field Effect

Transistor (MOSFET)

The MOSFET is a class of

FET transistors. The FET as the name implies conduction in a channel is

controlled to the gate electrode. There are no forward-biased junctions, so the

gate draws no current. The MOSFET is an important semi- conductor device and is

widely used in many circuit applications. In an inverter however, the MOSFETs

are used as switching device at the inverter output section.

The various terminal of MOSFET are;

i.

Source:

This is terminal which majority carried enter the bar. Since carrier come from

it, it is called the source.

ii.

Drain:

This is terminal through which majority carrier leave the bar i.e. they are

drained out from this terminal. The drain to source voltage V DS drives the

drain current ID.

iii.

Gate:

These are two internally connected heavily doped impurity regions, which form

two P-N junctions. The gate - source voltage VGS reverse biases the gates.

Figure 3.7 IRF540 Physical appearance of a MOSFET

The MOSFET is used in the inverter circuit as a switching device due to the following reasons;

i. It can work on very small drive power

ii. Its efficiency is higher at the high frequency.

iii. The input impedance of MOSFET is very high, so it can work without DC current.

iv. Switching time of the ordinary transistor gets affected by temperature, whereas the

temperature has very little effect on MOSFET device.

v. The ‘safe operating area’ of the MOSFET is larger than the bipolar transistor; hence the

MOSFET device does not get easily damaged.

3.11 The Battery

The battery used in this project is a two-terminal device that provides 12V DC supply to the inverter section when the AC mains is not available. This 12V DC is converted to 230V AC supply to the inverter output socket (Omitola et al., 2014). It is very important to state that lead-acid batteries used in automobiles are not good for this purpose as they provide good quality power for a short duration for the purpose of ignition and are recharged immediately when the automobiles are working. The backup time provided by the inverter depends on the battery type and its current capacity. The size of the battery bank will be determined by the daily watt-hour requirements and the desired days of storage capacity required. Here's a formula for calculating the battery needs: Take the adjusted watt-hours per day multiplied by the number of days of storage required; take that figure x 2 (for 50% depth of battery discharge); then divide by the system voltage = amp hours (ah) of storage needed. For example, let’s say you need 100 watt-hours per day and want 5 days of battery back-up;

100 × 5 = 500

𝑚𝑢𝑙𝑡𝑖𝑝𝑙𝑦𝑏𝑦 2 = 1000

For a 12V system = 1000/12 = 83 amp hour of storage required

If you are looking at 14ah capacity, 12V car battery,

We have 83/14 = 6

Therefore, we would need 6 of those 14ah 12V batteries to provide 5 days of back-up, at the discharge rate of 100 watts per day, in a 12V system. Ideally, it is recommended not take the batteries below 30% depth of discharge, and never below 50% depth of discharge. Basically we need to put a little more power into the batteries than you use (about 120 watts for every 100 watts you take out). Batteries can be series wired to achieve the desired voltage (i.e. two 6V batteries for 12V, two 12V for 24V, etc.). The lead-acid type of battery does require proper maintenance to extend their life and work in an optimum fashion. They prefer moderate temperatures around 70 degrees; for this reason they should be insulated in cold climates, and well-ventilated in warm climates. They need to be "equalized" at least three or four times a year, and as often as monthly. Equalizing refers to a "controlled overcharging" process whereby the voltage of the batteries is increased to where the accumulated sulfates are "cooked" off the plates and mixed back into the electrolyte solution. During this process, the battery caps are removed and distilled water is added as necessary. A hydrometer (tool for checking the specific gravity) is used to check the electrolyte density of individual battery cells at this time. The equalization voltage for a 12V system will usually be around 15 volts; for a 24V system, 30 volts.

3.13 Transformer

The transformer consists of small AC voltage of 12V which is received from the MOSFET. It is transformed and stepped up to an appropriate value ranging from 220V to 240V depending on our desire which is varied from the 1k resistor to the IC1 CD4047. The transformer is a device that alternates current from one voltage level to another. It has no rotating parts. It works on the principle of mutual induction. Transformer needs two coils which is wound on a laminated core. These coils are called primary coil and secondary coil. The coil to which the AC supply is provided is called primary coil/winding while the coil in which the emf is induced, and from which the output is taken is called secondary coil/winding. There is no direct electrical connection between the primary and secondary coil in a transformer.

E.M.F. EQUATION OF A TRANSFORMER

Let

N 1 = number of turns in primary

N 2 = number of turn in secondary

Øm = maximum flux in the core,

Wb = Bm x A

where;

Bm = maximum flux density in the core

A = Area of the core

f = frequency of A.C input, (in Hertz).

Therefore;

r.m.s value of e.m.f per turn = 1.11 x 4fØ max = 4.44fØ max volt

Hence, r.m.s value of induced e.m.f in the whole of the primary winding is

E1 = 4.44fØ max N1 …………………………………. (1)

r.m.s value of induced e.m.f in secondary winding is

E2 = 4.44fØmaxN2 ………………………………… (2)

For an ideal transformer on no-load, V 1 = E1 and V 2 = E 2

3.14 Determination of the Oscillating Frequency

By supplying a constant 12Volt DC through a voltage regulator to the IC1 CD4047, the frequency of the oscillating signal was determined using a 1KΩ variable resistor connected in series with another 330KΩ resistor and both connected in parallel with 0.01μF to form the RC time constant network.

Frequency, f = where

Time Capacitor (CT) = 0.01μF

Fixed Resistor (RF) = 330KΩ

Variable Resistor (VR) = 1KΩ

Time Resistor (RT) = 330KΩ+1KΩ = 330KΩ

Therefore, f = 1/(1×0.01×〖10〗^(-6)×330×〖10〗^3 ) f = 303Hz

It should be noted that the variable resistor was varied until the frequency of the signal was 50Hz (Omitola et al 2014).

3.15 The Drain Current of the MOSFET

From the Inverter, total power is 100Watts,

The battery Voltage is = 12V

Therefore, the drain current ID = P/V

ID =100/12

ID = 8.33A

Where the voltage output of the inverter, V output = 230V

Full load output current, I output

100/230

Ioutput = 0.435A

3.16 How to choose the best inverter battery

Nowadays, it is almost unimaginable to survive without power supply in our homes or workplaces. However, the moment power supply to our appliances and other gadgets that makes our everyday lives a lot easier and relaxed goes off, our lives becomes boring. Such situation leaves us really bothered unless there is an inverter with a powerful inverter battery.

Here is a list of some most important things to consider when choosing the best inverter battery is as follows;

i. Understand the power requirement

ii. Be aware of the inverter battery size that you require.

iii. Find the VA rating of the inverter you require.

iv. Consider the bigger appliances

3.18 The Change Over

This section is used to switch ON the inverter when the AC mains supply is OFF and to switch OFF the inverter when the AC mains supply comes back ON. During changeover, when the inverter receives AC mains supply, it stops drawing the battery supply and the AC mains supply at the inverter input is directly sent to the inverter output socket. This is done using a one, two pole change over relay.

3.19 Inverter AC Output

The AC output gives a 230V AC, 50Hz either directly from the input when the AC mains supply is available or from the inverter circuit action on the battery when the AC mains supply is not available. Computers and other household appliances are connected to this output.

3.20 Protections

The AC input to this device was fused with a 5Amp fuse to protect the transformer as well as the rectifying circuit in case of over voltage, and high current which could flow into the transformer.

3.21 Indicators

Five indicators are connected to the front of the inverter; a red colour shows that the inverter is charging as well as delivering a 230V AC from its output terminal. Green colour indicates that the inverter is discharging from the battery. Yellow colour indicates that it is inverting. White colour indicates battery full and the last red colour indicates battery low.

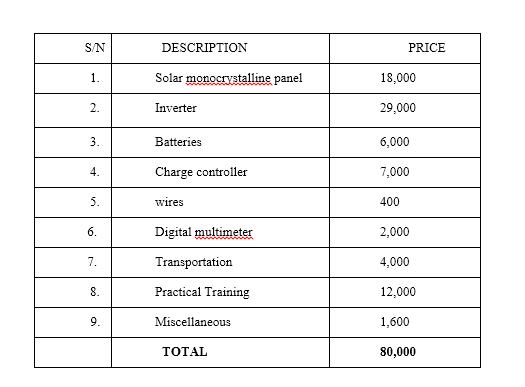

3.22 Switch